Author: AFCM Leonard J. Puncochar USN (Ret.) My story begins on a particular night in 1963 at NAVSTA Sangley Point, Philippines. I was attached to VP-40 and assigned to the Night Check’s maintenance ground crew. As the senior AMH1, I was Supervisor of the Air Frames Shop; on this particular night a serious aircraft incident

Author: AFCM Leonard J. Puncochar USN (Ret.)

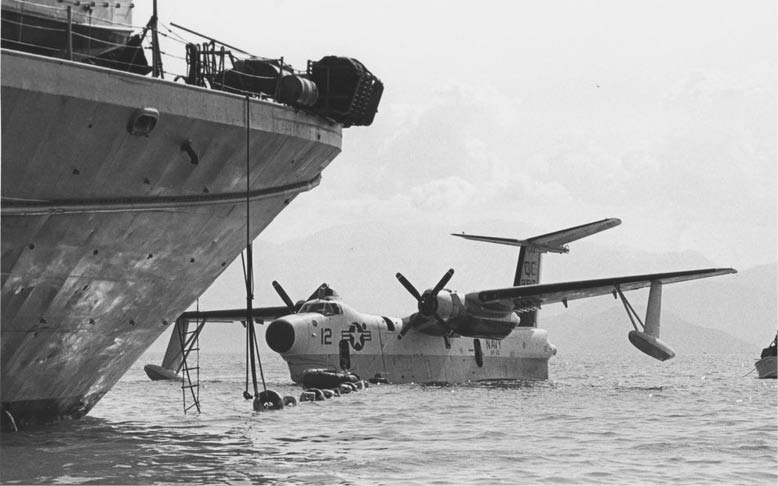

My story begins on a particular night in 1963 at NAVSTA Sangley Point, Philippines. I was attached to VP-40 and assigned to the Night Check’s maintenance ground crew. As the senior AMH1, I was Supervisor of the Air Frames Shop; on this particular night a serious aircraft incident occurred.

On a side note, something I never quite understood was why AMs were tasked with the job of maintaining fuel systems?

Maybe higher-up pay grades thought hydraulics and fuel systems were the same. On this particular evening we were working on QE-8. The work order stated there was a fuel leak coming from the hand pump located behind the port beaching gear bulkhead. The pump was used to manually transfer fuel to different fuel tanks within the P5M. Upon investigating the problem, we determined the leak was coming from the faceplate of the pump. The faceplate was secured with approximately fifteen small screws; all held in place with a single strand of safety wire. We decided that the screws needed to be tightened to rectify the problem. Before I returned to the shop, I assigned one of the mechanics to repair the problem. He was given the instructions to very lightly re-torque the screws because they could be easily broken. The mechanic returned to the shop a short time later saying that he had broken the head off one the screws.

Now we were screwed!

This P5M was scheduled for an early morning flight. Night check was told QE-8 had a high priority and all work orders were to be corrected that evening. As the senior AM on night check I made the decision we needed to replace the fuel pump. Prior to replacing the old pump with a new one we made sure the fueling valve was shut off. Furthermore, we used water pump pliers to compress the flexible hose in order to minimize any fuel leakage. The plan was to rapidly spin off the hose nuts from the old fuel pump, and quickly re-attach the hose to the new pump, and then secure the pump back into place. In the process we were amazed at the amount of fuel that leaked out while installing the new pump. In anticipation of any possible a fuel spillage within the P5M we had a 100 foot garden type water hose (connected to a water faucet at the edge of the tarmac), just in case there was need to clean-up any fuel spillage. As it turned out we needed the water! We proceeded to wash down the fueling area (inside the plane) letting the water enter into the bilge. After awhile, one of my AM’s in the aft end of the P5M came forward and told me the water was flooding the rear of the aircraft and was already up to the main door entrance.

We hadn’t turned off the hose and water had filled the bilges and in-turn was flooding the P5M. The water hose was turned off, then we proceeded to pump the water out of the bottom of the P5M using the aircraft bilge pump. Near the end of clearing out the water, the pump sucked up a loose screw that shattered the fragile carbon vanes of the bilge pump. I didn’t think this presented any real problem. We had a squadron of bilge pumps. I sent one of the mechanics to the adjacent P5M to get their bilge pump. At this time there were four of us AM’s in the aircraft; three were aft and I was forward. We had all the decking pulled up. The new bilge pump was plugged in. The bilge pump was turned on.

This time we were really, really screwed! A streak of fire shot out of the bilge pump and the midsection of the P5M went up in flames. It was like having a room filled with propane gas and throwing a match in.

One of the mechanics was blown out of main aircraft door. I checked the rest of the aircraft to make sure no one had fallen into the bilges which were in flames. Then I dove out of the port beaching gear hatch head first but landing on my feet. I raced to the nearest telephone which was in the bowling alley approximately forty yards away and then I realized that the bowling alley was closed. Being that it was in the middle of the night, it was amazing that a crowd had already gathered and the fire trucks had arrived. Luckily, none of us were hurt; the AM blown out the aircraft only sustained minor singed eyebrows, the other two AMs exited through the man door under their own power.

To my dismay the Safety Officer, who was also the Senior Plane Commander of QE-8, was there wringing his hands and making comments about his “beautiful airplane” burning. He was going nuts and I knew I was in deep do-do.

Knowing or at least expecting me and/or the AM night check crew would be held responsible for the damage done to QE-8. I had a quick meeting with the three other AM’s that were involved with the incident before anyone else talked to us. The purpose of meeting was so that we would have a common story of what happened. I guess it depends if you are buying or selling, but there is a lesson to be learned. If you are to be considered as the guilty party then it would best if you have your stories straight. That does not mean you have to lie. If you are the one to conduct the initial safety review it might be best to separate all parties concerned as soon as possible after the incident. Sure enough, about 0500, which was about three hours after the incident, the AM’s involved were summoned for a meeting with the Safety Officer. This confirmed we were in trouble. His last question to us was “anyone smoking in the aircraft?” Rather an odd question when you’re working around an AVGAS leak. We didn’t hear anything further for several weeks then one early morning while I was having a drink at a local VP-40 hang-out (remember I work night check) a sailor from the Communications Department entered. When he saw me at the bar he confided to me that a green sheet (classified document in reference to the incident) had just come in from the “Commander Taiwan Patrol” where the Admiral wanted disciplinary action. I could envision my first class stripes disappearing or worse. Sure enough the very next day the Legal Officer summoned me to his office. He told me because the Commanding Officer was leaving in about a week, they needed to hurry the process of bringing charges against me. First I would have a Captain’s Mast and the following day I would have a Court Martial. From my military training, it was the Captain’s prerogative to hold a Court-Martial, not the Legal Officer. Furthermore, he said our discussion was confidential and I wasn’t to tell anyone about our conversation. He further told me he had already written the charges against me and that I would be found guilty without any doubt. However, I did tell my Division Officer about the Legal Officer’s meeting and he sympathized with me in my unique predicament.

Although I was never told officially that QE-8 was going to be stricken. It was common scuttlebutt that the damages were so great that if this had happened in the States, the aircraft would have been declared a strike. To mention a few major repairs: A portion of the hull had to be replaced; The hydraulic service center had to be replaced; Fuel tanks (bladder) might need to be replaced. In the few weeks between incident and charges brought against me, I did some investigation of my own. Of particular interest was the “NAVAIR 03” manual on the bilge pump. The opening paragraph nearly knocked my socks off. It stated that the bilge pump (which I doubt anyone was aware of) had two purposes. The primary purpose was to fuel aircraft in remote areas. The pump had carbon vanes and an explosive proof motor. The secondary purpose of the bilge pump was to pump out salt water from the bilges. Then I found there was a Single Action Maintenance Instruction (SAMI) for the Squadron’s bilge pumps. It had been discovered that some of the bilge pumps were wired with the polarities reversed. Back at the barracks, talking to a few of the plane captains, they informed me I should’ve known better because in their experience, the pumps always shot fire out when turned on.

The long and short of it, the SAMI stated the Airframes Officer was supposed to turn the bilge pumps over to the Avionics Officer who was to determine if the wiring was correct, if not, the Avionics Shop would make the correction. Then the bilge pumps were to be sent back to the Airframes Shop which would paint an International Orange stripe around the pump indicating the wiring was correct. Maintenance Control Office was supposed to monitor each of the bilge pumps to insure they were in compliance with the SAMI. Obviously something fell through the cracks. And I was the fall guy. Seeing the writing on the wall, where everything was stacked against me, I let it be known that I was going to plead guilty to minimize the charges against me. A gruffly old senior chief grabbed me by the neck and told me never plead guilty. I took the wise Senior Chief’s advice and decided to change my plea.

At the Captain’s Mast I was asked how I pleaded and I responded with “Not Guilty”. I thought the Legal Officer was going to have a heart attack. The Captain’s Mast lasted a long time but in the end I was found guilty of: 1. Using the APU to provide electrical power to the bilge pump. 2. With an AVGAS leak I should have never put electrical power to the aircraft. 3. I should have properly vented the aircraft. The captain told me I was going to get a “Letter of Reprimand”. Which I thought was reserved for officers; I’d never heard of an enlisted getting a “Letter of Reprimand”. So I waited around unit the entire Captain’s Mast was finished. The Legal Officer come over to me and put his arm around me and told me that he wrote the charges so I would get off easy. Later I was summoned back to the Captains office. He explained to me that he was leaving in a few days and the Admiral had pushed to hold someone responsible for the destruction the P5M. The Captain went on to say that there were so many people involved with the incident and to be totally frank I was the low man on the totem pole. The Captain instructed me that he would be calling me back later for a formal reading of the “Letter Reprimand” but he would write it in a manner that wouldn’t hurt me for advancement to chief.

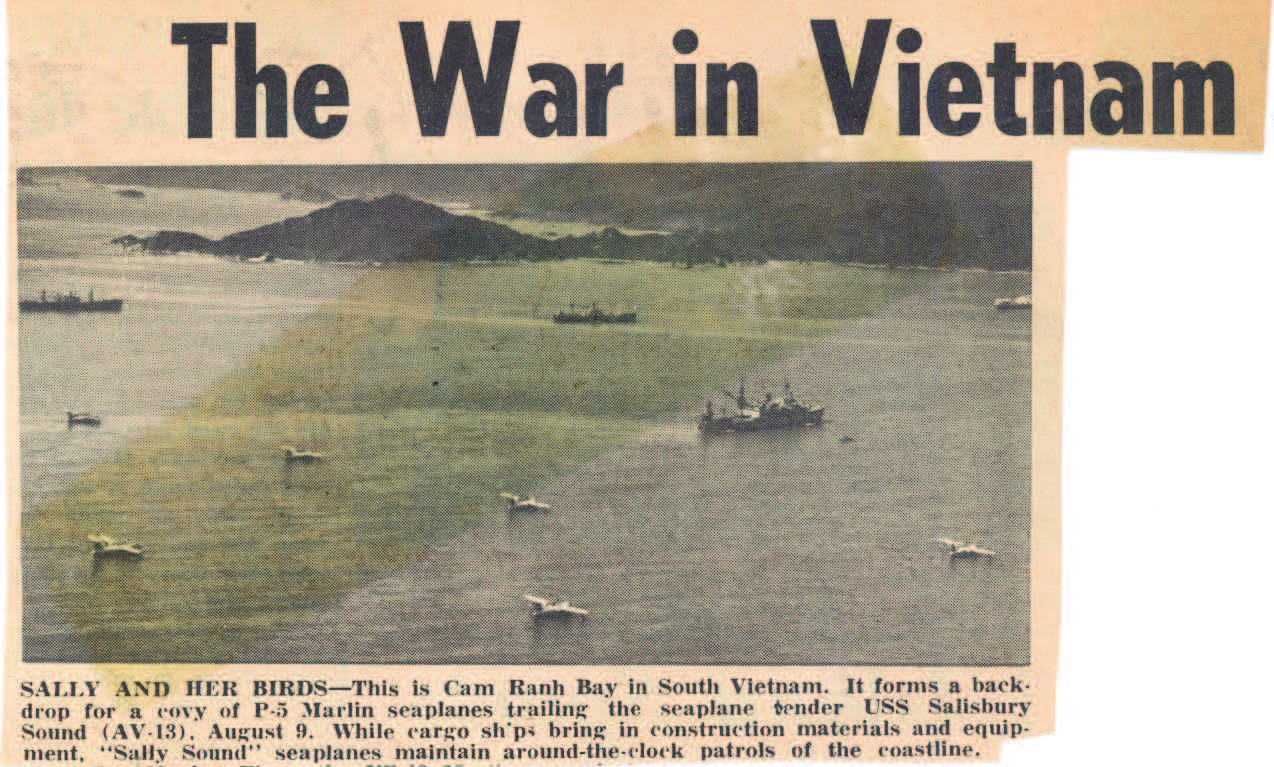

Now the Rest of the Story! As a result of this incident it was found that the squadron was in error, having the AM’s maintaining the fuel system instead of the AD’s. This caused the AD’s to be in dismay because now they had an extra aircraft system to maintain and the AM’s were happy as hell. I believe the confusion was that the rating manual stated the AM’s maintain a wet wing fuel system and the AD’s maintain a bladder tank System. If this incident happened in the USA there is no doubt QE-8 would have been stricken. But it didn’t happen in the USA, it happened in the Philippines. It was decided that it was economically feasible to repair the aircraft using local labor subcontracted by Philippine Airlines (PAL). Thanks to the Filipino PAL workers, QE-8 was saved. These workers did a super job in repairing this aircraft and really deserve credit. I believe QE-8 was repaired by the Filipino’s at a cost of about $100,000.00. This incident happened in 1963 and by the end of the year all remaining P5M’s were West Coast Squadrons and the seaplane era was coming to an end. The P5Ms played an active part in the Vietnam War. On November 6, 1967, VP-40 flew QE-10 on its last official flight, using the last qualified P5M-2 crew, and landed in San Diego Bay. QE-10 is on exhibit at the National Naval Aviation Museum in Pensacola, Florida.

Leave a Comment

Your email address will not be published. Required fields are marked with *